WineCraft

Winery in context

Perspective Section

Fermentation Levels

Malolactic Fermentation Floor

Bottling Floor

Section

Winery Axonometric Section

Design Process

- Introduction

- Section I: Vineyard Concept

- Section II: Winery Design

- Gravity-fed production

- Wine ageing cellar optimisation

- Section III: Detailed design

- Structural and construction strategies

- Water drainage

- Energy and environmental strategy

Introduction

Death of Rural Bulgaria

Following the introduction of communism in Bulgaria in 1946 all rural land was reoganised into farming cooperative land, either forcefully or voluntary. The country began to grow and export fruits, vegetables and meat and about 42% of the country population in 1975 lived in villages and rural regions.

After the fall of communism in 1989 the land was returned to its former owners or more likely their heirs, majority of who had little to no interest in continuing the previous agricultural use of the land. During the 1990s many people moved to the cities to work and left behind their homes.

Fast-forwarding nearly 30 years to 2018, at least 150 villages have virtually no population at all and about 1133 or 21,5% of all settlements in the country have less than 50 inhabitants.

Without further intervention the low fertility and high mortality rates and a lack of employment in rural areas by 2060 there will be no villages left in Bulgaria.

Studies of the countryside

In 2012 the Stedelijk Museum in Amsterdam hosted a lecture on the Countryside by the OMA (2012). The study shows a significant jump from the way agriculture and farming in the 18th century were practiced to the present day. Much of the work of the typical farmers back in the days is now mechanised and automated. Nowadays, farmers spend most of their time on business management and administration sitting behind a computer.

Mechanisation and automation industry

At this point, the research focused on understanding how the agriculture industry is mechanised and automated as a good understanding of these would have a great impact on the vineyard and winery design. According to Rifkin (2014), a new industrial revolution is now emerging. He predicts a shift from capitalism to collaborative commons. This new industrial revolution is caused by the rapid development of technologies in communication, energy and transport, allowing devices to communicate with each other and send data to users. Rifkin calls this the Internet of Things.

In agriculture, farmers are using sensors to monitor weather condition changes in soil moisture, the spread of pollen and other factors that affect the yields, and automated response mechanisms are being installed to ensure proper growing conditions. Sensors are being attached to vegetables and fruit cartons in transit to both track their whereabouts and sniff the produce to warm of imminent spoilage so shipments can be rerouted of closer vendors. (Rifkin, 2014) Sensors are also being placed to detect subtle changes in vibrations and earth density to provide early warning systems for avalanches (snow slides), volcanic eruptions and earthquakes in some regions of the world. (Rifkin, 2014)

Proposal

The project started with an idea of regenerating a rural historical site in a proximity to mountain peak Vola, in the North-West part of the country which is poorly maintained with a number of existing dwellings in uninhabitable condition. The proposed architecture and landscaping provides a modern 21st century winery and vineyard. The existing topography, climate and agricultural past of the area underpin the choice of programme, while current low-cost of sensors and smart technologies allow for speculation of previously unexplored wine-making typologies.

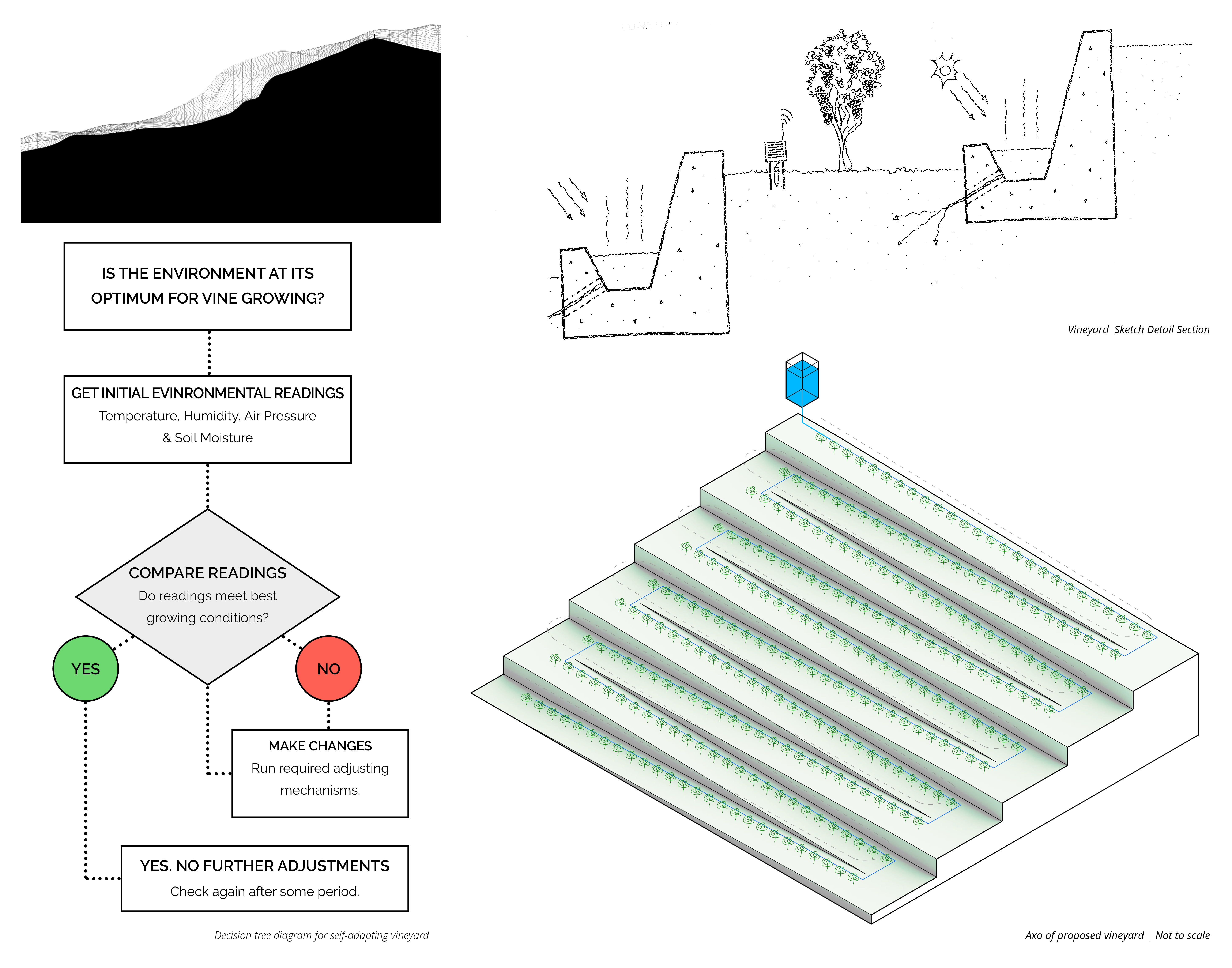

Section I: Vineyard Concept

Site Axonometric

Autonomous Vineyard

Wine producing regions are commonly found between 30° – 50° latitudes (Bulgaria is between 41-44° N). Presence of large bodies of water and mountain ranges can positively affect the micro climate for wine making. Hillsides and slope are preferred are usually preferred for vineyards as the vines growing can receive greater intensity of sun rays. The principle of the proposed autonomous vineyard comes from self-adaptation or self-regulating system ( thermostat for example). Sensor devices could be installed on site to measure different aspects of environment such as air-temperature, relative humidity, barometric pressure, soil moisture, light and others. These devices could be programmed to perform certain actions based on embedded parameters such as controlling water irrigation system will could in turn flow natural down to the site topography.

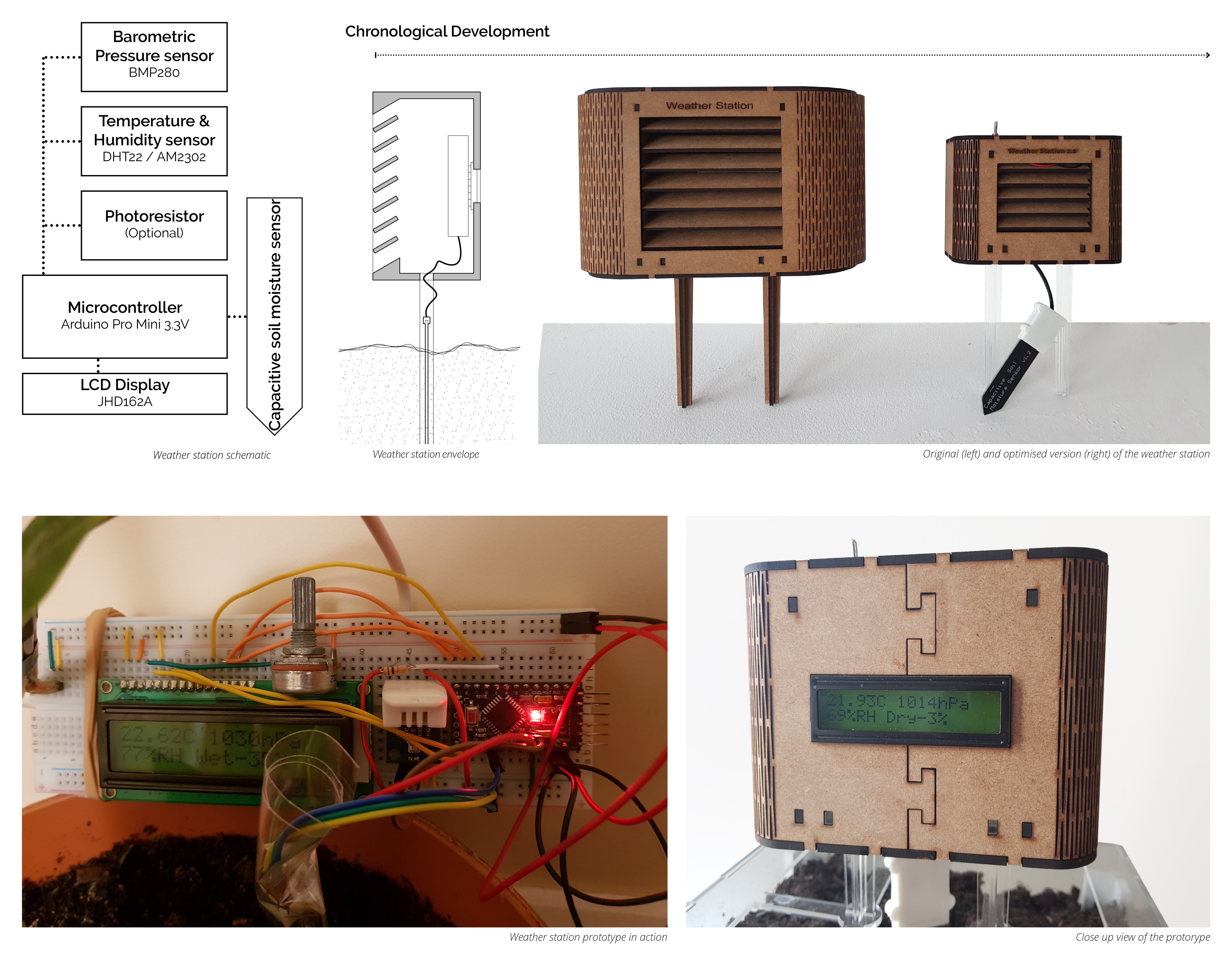

Arduino Weather Station

Microcontrollers such as Arduino are typical options for low-cost and low-power special purpose computing. They are able to read input signals from various sensors and communication modules and output signals to control water irrigation systems.

Section II: Winery Design

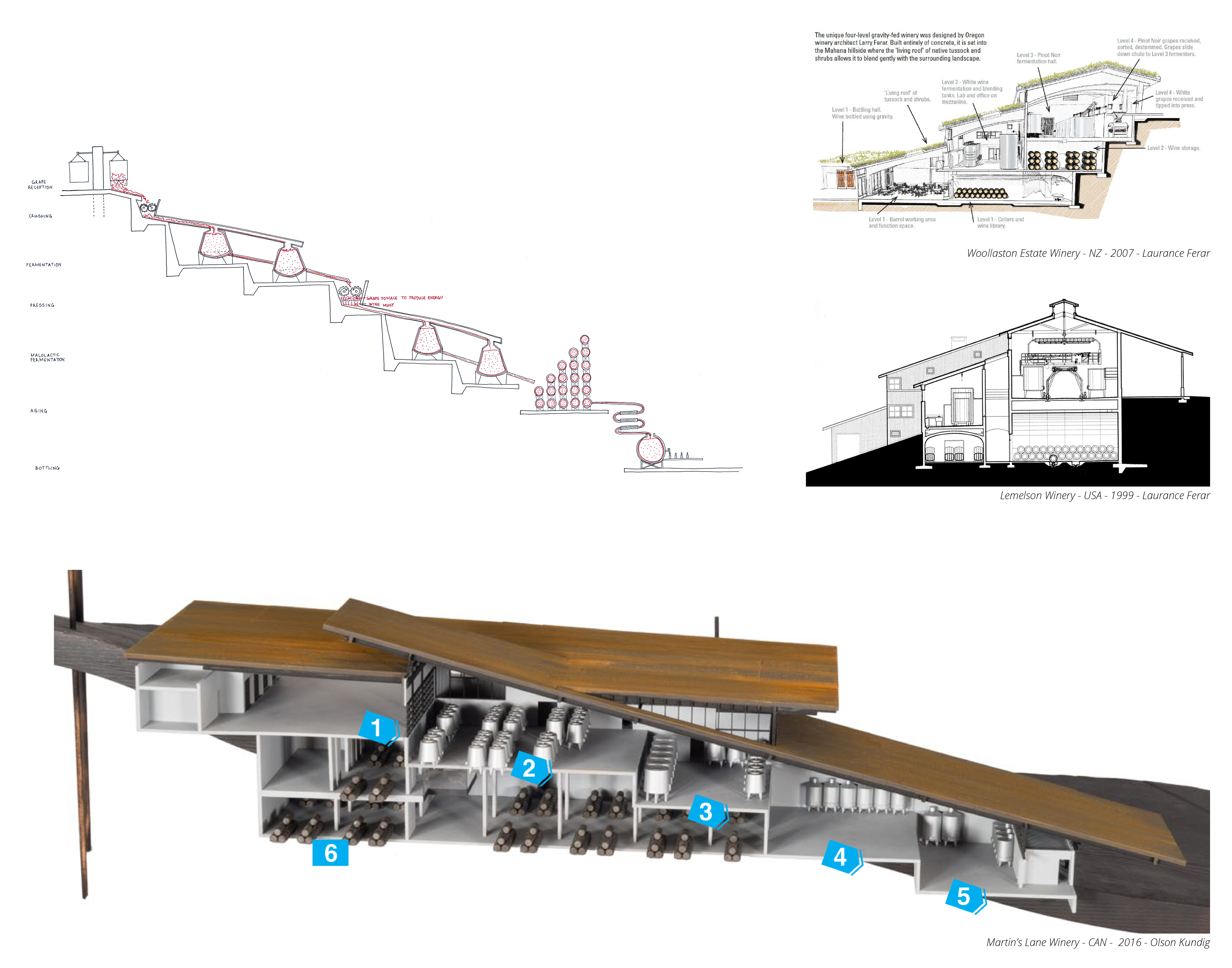

Gravity-fed production

Gravity-flow wineries provide a gentler, less interventionist approach to wine-making, takes less work moving around pumps and hoses and requires less electricity. But gravity-flow wineries can be expensive to build and require a wine-making team willing to walk up and down stairs and ladders. Their designs typically work best when built into an existing hillside, and some of the best wine regions are in valleys. Cellars are one of the most important spaces in wineries. This is the space where wine ages for a year. For best wine quality cellars are usually kept under constant cool temperature as sudden changes in the temp can ruin the wine taste. To achieve best conditions for wine aging cellars’ temperatures can be controlled in 2 ways: mechanically which requires a lot of energy or passively cooled by being built under the ground in which case the cost of a winery can increase drastically due to the amount of excavation. Since the project is based on a slope it could utilise passive cooling, which will also reduce the energy consumption of the winery in the long run.

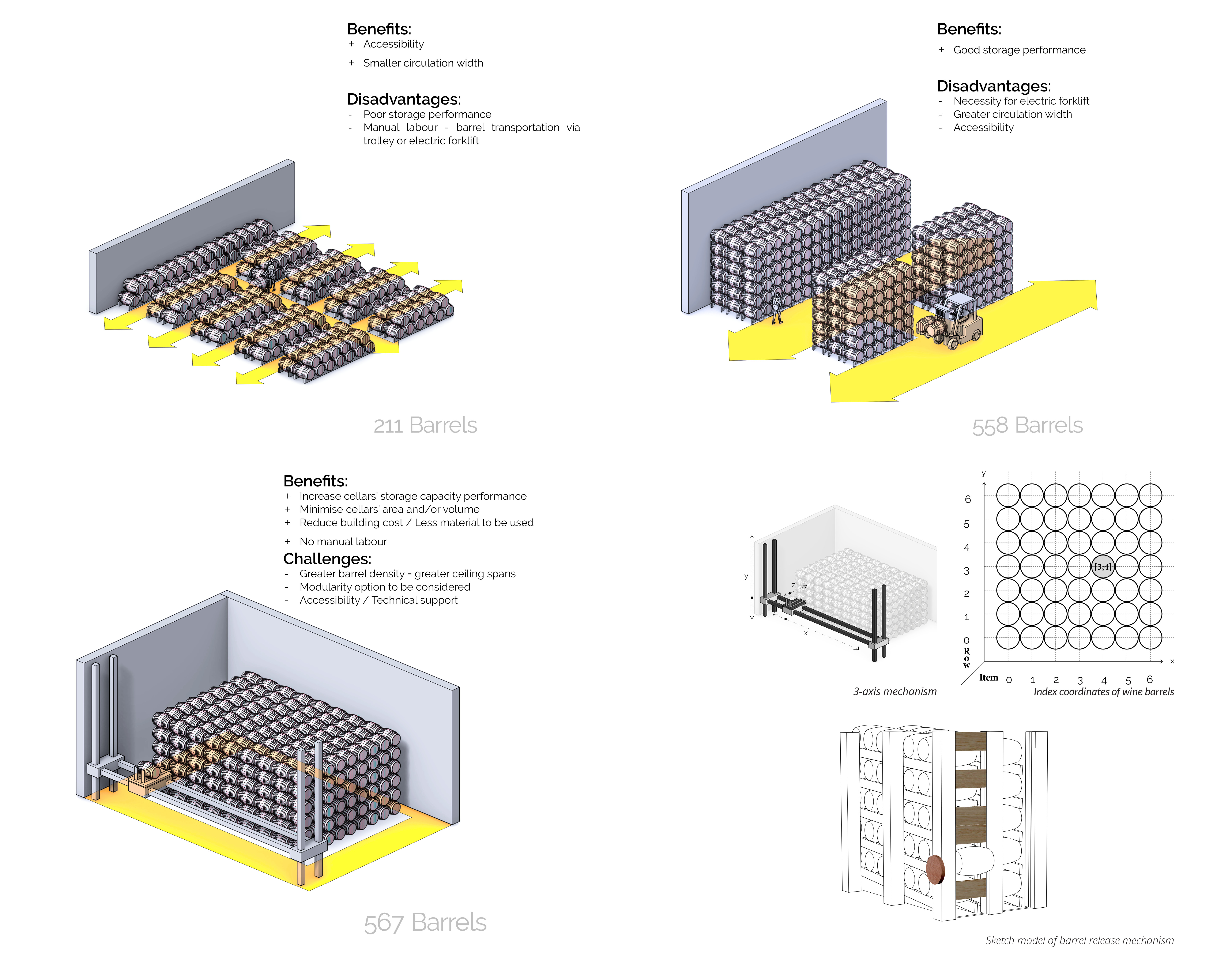

Wine aging cellar optimisation

Digital Cellar Concept

Section III: Detailed design

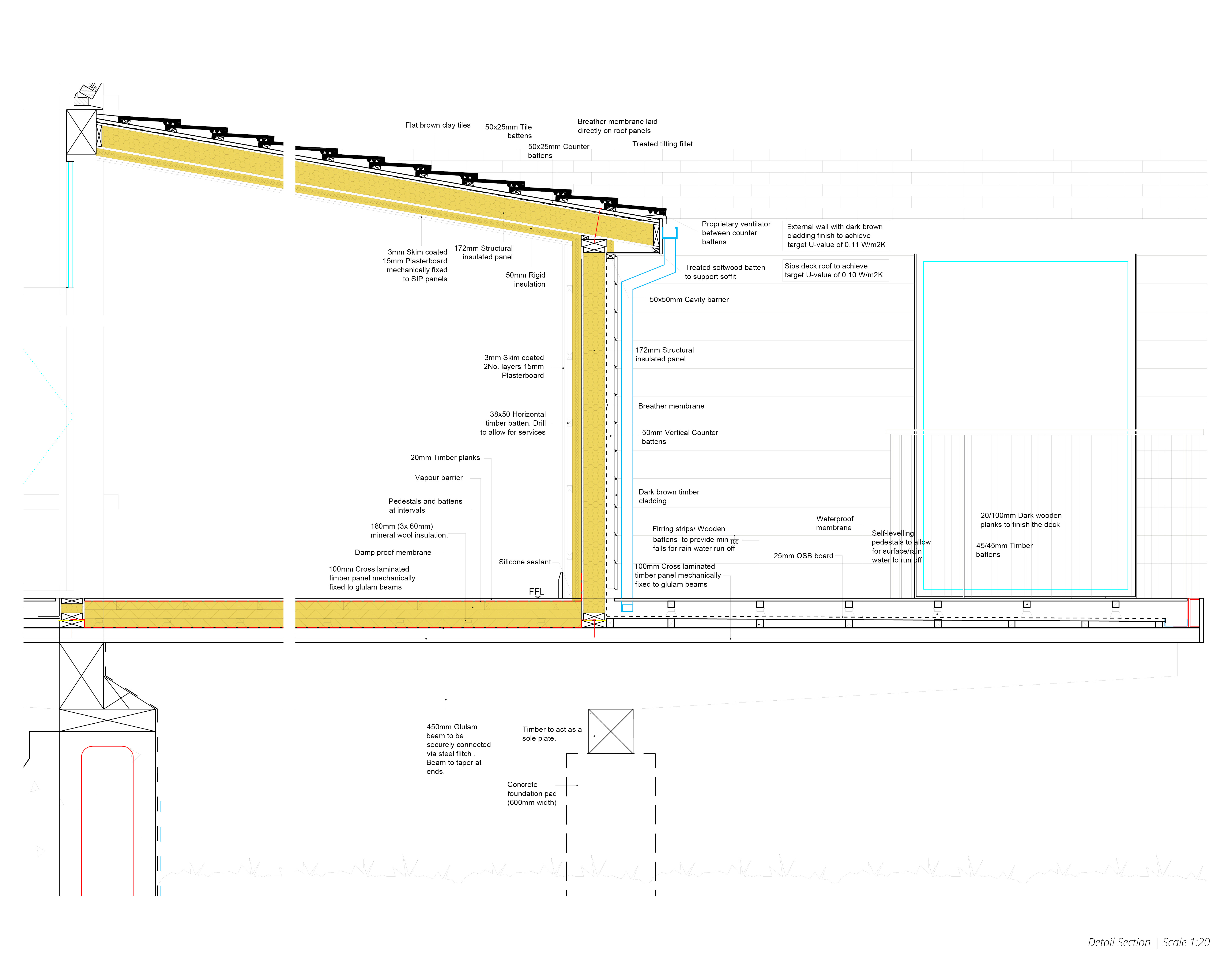

Structural and construction strategies

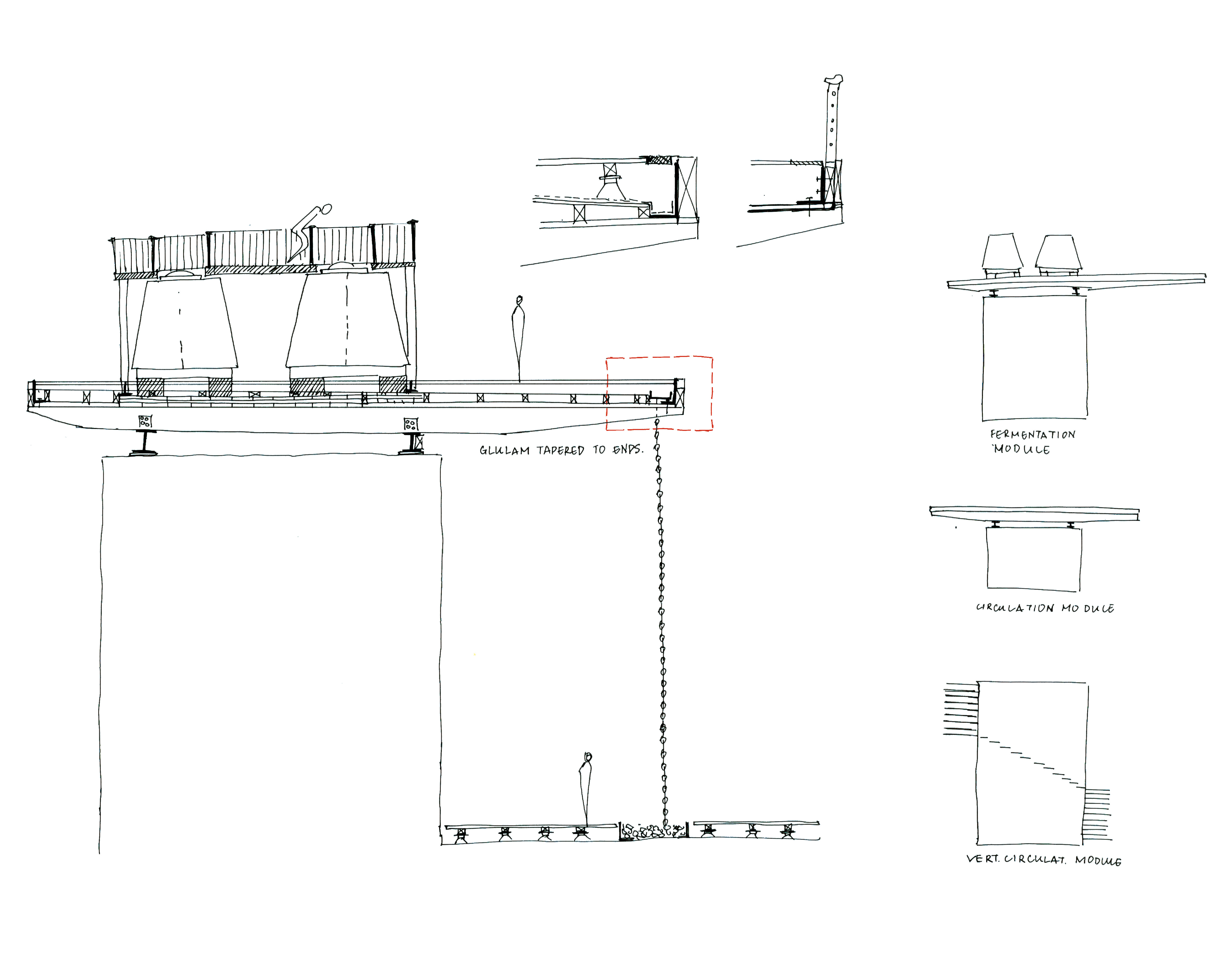

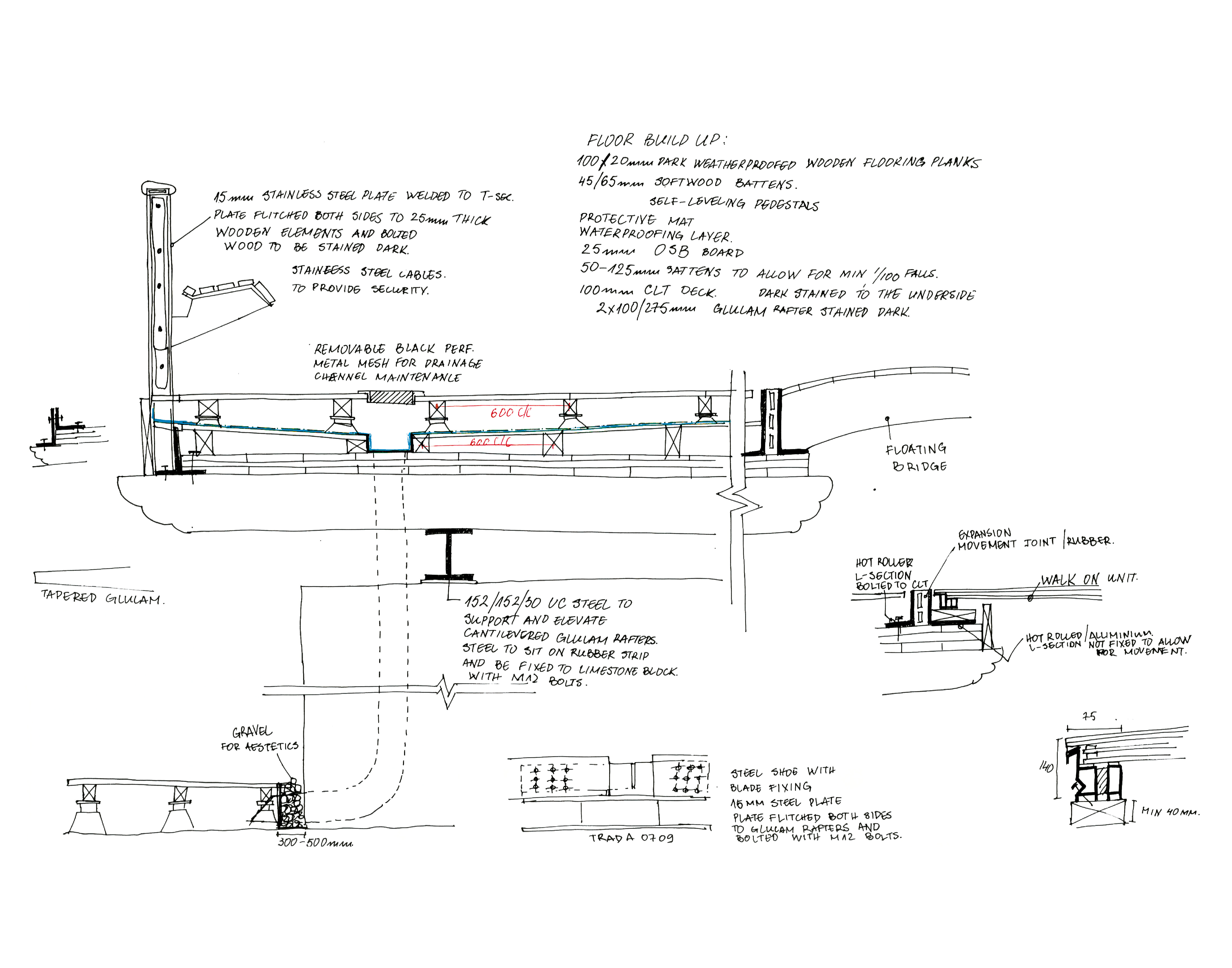

Construction sketches

Fermentation Unit Detail Sketches

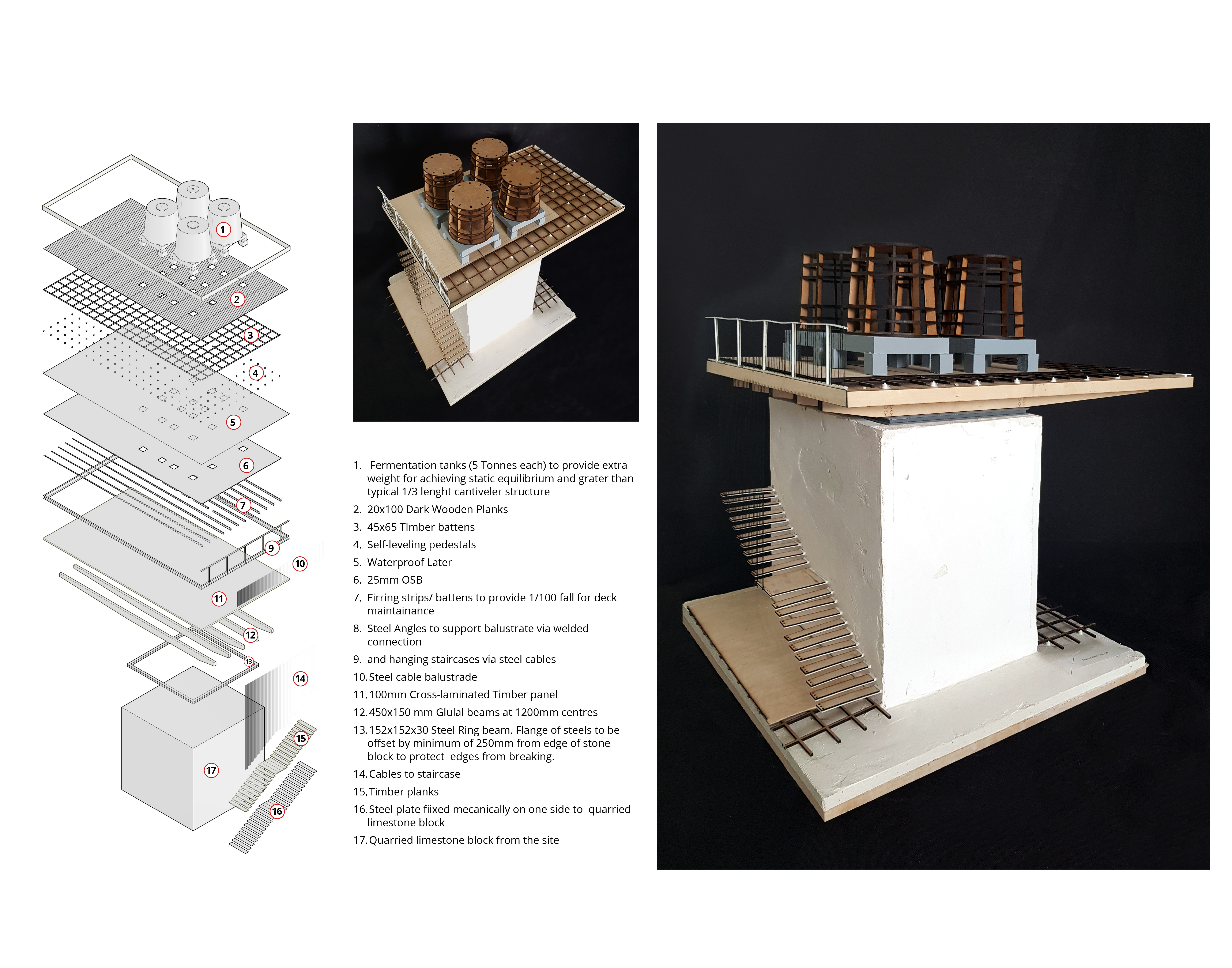

Fermentation unit construction sequence and model

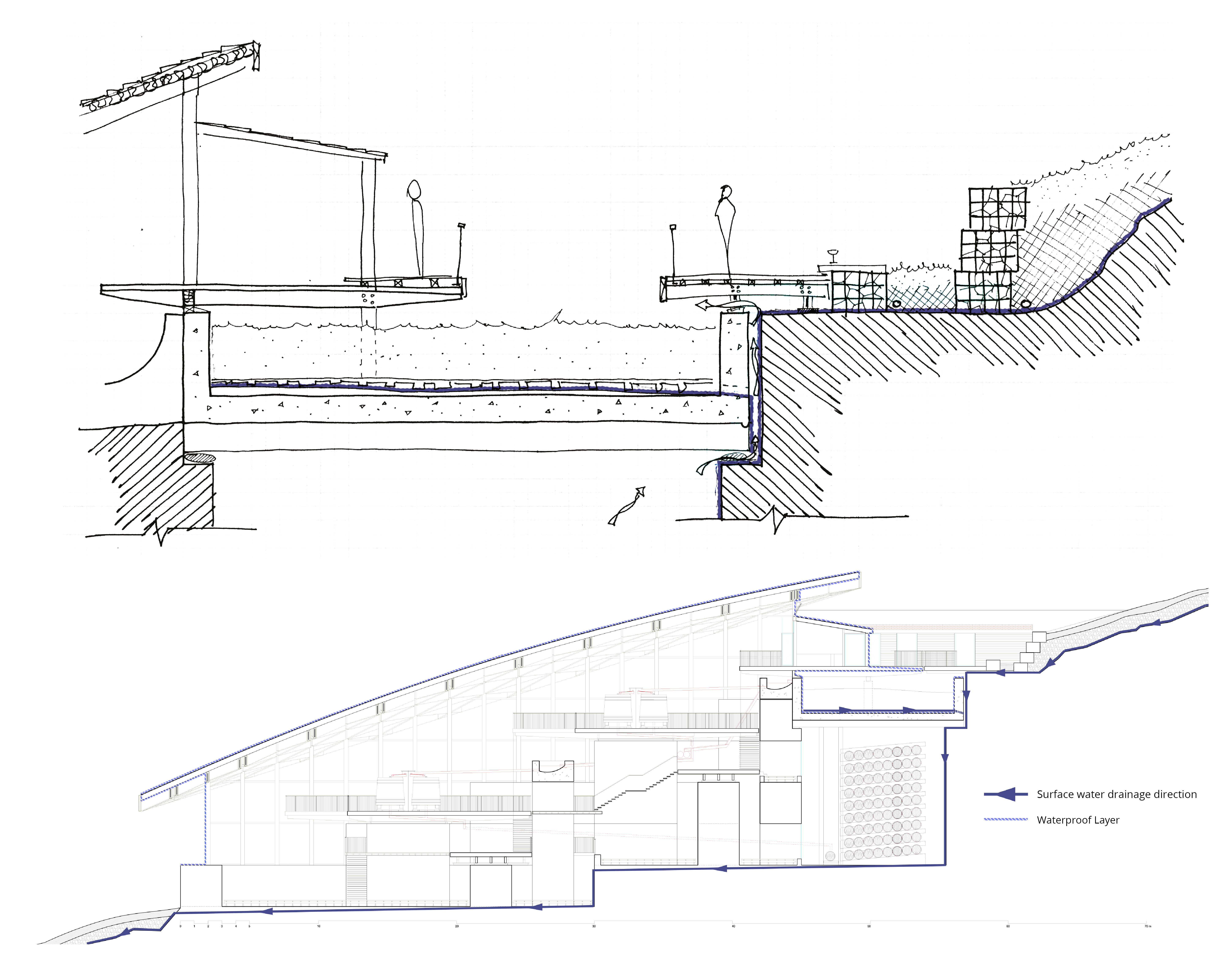

Water Drainage Strategy

The site topography is already used for gravity-fed production process but it could also be used to allow water to flow natural through the building. This will be achieved by cutting irrigation channels at min 1/100 falls once the site is quarried. The ground level floors will be timber decks raised on self-leveling pedestals. The green roof (concrete pool-like) structure will sit on neoprene pad commonly used in bridge constructions. This will prevent chipping stone edges and allow for water to flow through. Small 200mm wide gap between the concrete upstand and quarried rock will be used for ventilation to prevent damp.

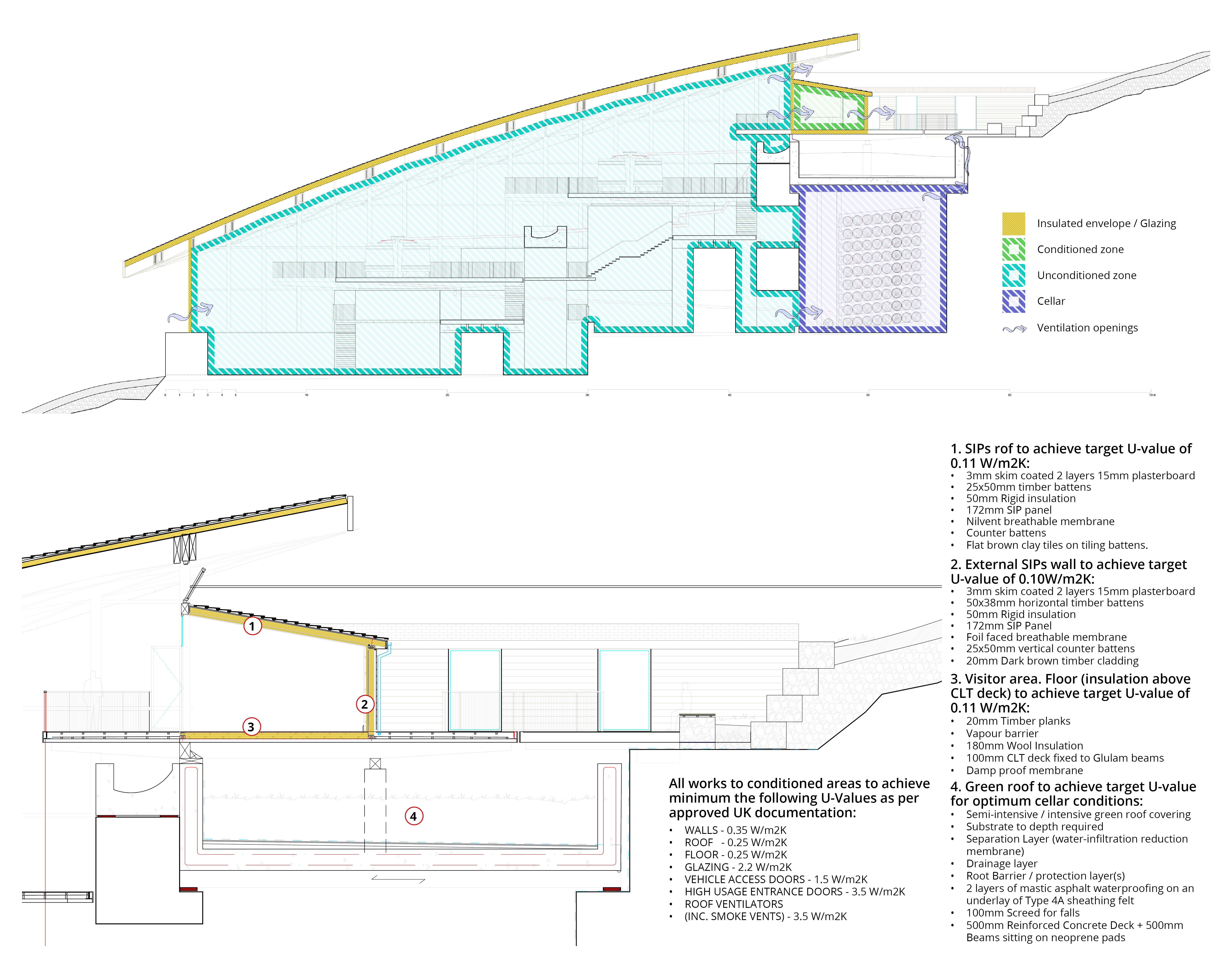

Energy and environmental strategy

The main wine production zone will remain unconditioned due to meeting required conditions for fermentation (see next page) by avoiding extensive heat gains from August to Oct and its large volume. There will be however controlled ventilation openings. To prevent heat gains the proposed roof is to be insulated and curtain wall to be installed to the perimeter to complete the external envelope. The wine aging cellar will be built into the natural stone and will have a stone wall surrounding it. A deep green roof will be provided for thermal mass keeping temperature changes to a minimum. Entrance area and visitor centre at the top part of the building will be the only conditioned space, thus be built with SIPs and insulated where required. Glazed doors will be provided to allow for natural cross ventilation during the summer months. Anaerobic digestion tank will be installed on site to produce biogas from grape pomace and be used for heating during winter months.

Detail Section